Industrial Coffee Grinder Guide: Boost Performance and Top Quality

In the affordable landscape of coffee production, selecting the right industrial coffee mill plays an essential duty in boosting both efficiency and item high quality. Recognizing the nuances of various mill kinds and key features-- such as adjustable grind settings and durable building and construction-- can considerably influence the last taste profile of the coffee. The optimization of the grinding process, combined with attentive maintenance, is important for sustaining performance over time. As we explore these critical elements, it becomes apparent that the ramifications expand beyond plain devices choice, impacting total service success in methods that call for closer evaluation.

Understanding Grinder Types

When choosing an industrial coffee grinder, comprehending the different kinds readily available is essential for enhancing both flavor extraction and functional performance. The 2 key kinds of grinders are blade mills and burr mills.

Inevitably, selecting the ideal kind of grinder is integral to maintaining top quality and effectiveness in coffee manufacturing, making it important for businesses to spend in high-grade burr mills for optimum outcomes.

Trick Features to Take Into Consideration

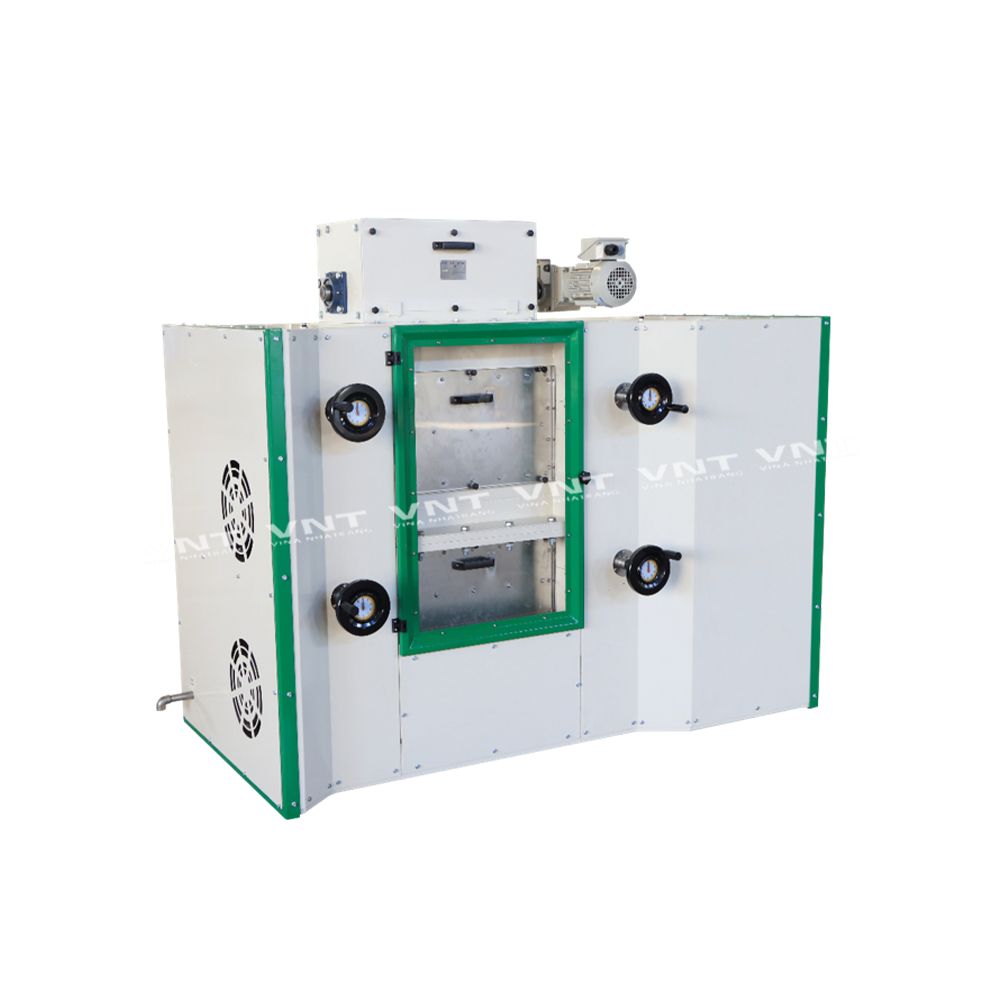

Choosing a commercial coffee grinder calls for careful factor to consider of several vital features that can significantly influence both performance and the overall coffee experience. One of the main elements to review is the grinding device. Burr mills are generally preferred over blade grinders, as they give a regular grind dimension, which is essential for optimal removal and flavor.

An additional vital function is the mill's capability. Depending upon the quantity of coffee you require to process, pick a design that can manage your demands without sacrificing speed or high quality. In addition, think about the work settings used. A functional grinder with numerous settings enables you to customize the work size to various developing techniques, improving the coffee's flavor account.

The construction material also plays a role in durability and maintenance. Stainless-steel components frequently offer longevity and are easier to clean, which is important for keeping hygiene standards. Examine the grinder's sound level, especially in an active café or production environment, where excessive sound can be disruptive. Purchasing a grinder that stabilizes these functions can substantially boost both functional efficiency and the high quality of the coffee served.

Optimizing Grinding Process

To achieve the best results in coffee prep work, enhancing the grinding process is essential. The grind size considerably influences removal, taste, and total top quality of the brewed coffee.

Furthermore, monitoring the grinding speed can optimize the process. Slower grinding commonly generates much less heat, protecting fragile tastes and fragrances. On the other hand, faster grinding might generate too much heat, negatively impacting the coffee's quality.

Upkeep and Care Tips

Proper maintenance and treatment of commercial coffee grinders are crucial for making sure optimal efficiency and long life. Regular cleansing is the why not try these out structure of maintenance; residue build-up can influence taste and grinding performance. It is recommended to clean the mill after each use, wiping down the outside and getting rid of any kind of coffee grounds from the burrs.

Furthermore, examine the grinding burrs for damage. Boring burrs can compromise work consistency, so they must be changed as essential. Industrial Coffee Grinder. Periodically calibrating the mill is additionally critical, as this maintains the preferred work size for numerous brewing techniques

Lubrication of relocating parts need to be executed according to the maker's requirements, as this lowers friction and lengthens the life of the tools. It is vital to make use of food-grade lubricating substances to guarantee security and compliance with health and wellness policies.

Lastly, maintain the grinder in a dry and secure atmosphere to avoid corrosion and rust. By adhering to these upkeep and treatment tips, drivers can enhance the efficiency of their commercial coffee grinders while ensuring top quality result and prolonged functional check my site life.

Return on Investment Analysis

Examining the return on investment (ROI) for industrial coffee mills is critical for businesses looking for to optimize their coffee manufacturing capabilities. An extensive ROI evaluation helps determine the economic stability of buying high-quality mills, permitting organizations to consider the first prices against prospective gains.

Assess the purchase cost of the mill, including setup and any kind of necessary modifications to existing facilities. High-performance mills usually lead to decreased grinding time and increased throughput, which can dramatically improve efficiency.

Furthermore, think about the influence on item top quality. Industrial Coffee Grinder. Superior mills generate an even more consistent grind dimension, which can enhance flavor profiles and client fulfillment, ultimately driving sales. By boosting the high quality of the last item, companies can justify greater pricing, bring about enhanced earnings

Verdict

In summary, an industrial coffee grinder plays a critical duty in improving both performance and product high quality within coffee manufacturing. By selecting premium my company burr grinders geared up with vital functions such as flexible grind setups and resilient building and construction, businesses can guarantee optimum flavor extraction. Routine upkeep is vital for maintaining grinder performance and maximizing consumer complete satisfaction. Inevitably, the strategic investment in a reliable mill adds significantly to improved earnings and competitiveness in the coffee industry.

In the affordable landscape of coffee production, picking the right commercial coffee mill plays a crucial duty in enhancing both effectiveness and product high quality. The two main types of mills are blade mills and burr mills. Within the burr mill group, there are flat burr grinders and conical burr grinders, each with its benefits. Burr grinders are normally favored over blade grinders, as they offer a constant grind dimension, which is vital for optimal removal and flavor.

In summary, an industrial coffee grinder plays a pivotal duty in boosting both effectiveness and item top quality within coffee production.